We do understand the stability and reliability of our product based on the strict quality control, so the application of our quality system in every phase of production focuses on customer’s request.

Certifications maintain and audited pass:

- ISO9001 : 2015

- IATF16949:2016

- COC auditeed by ITS

- GSV C-TPAAT audited by ITS

Expert is the keyword in our engineering departure. Our qualified and diversified team of engineers and technicians allows Winlong to always find the expert solutions of the customers’ demands. Equipped with the latest technological tools to address industry demands and give us the capabilities to predict the performance of the product in real life condition:

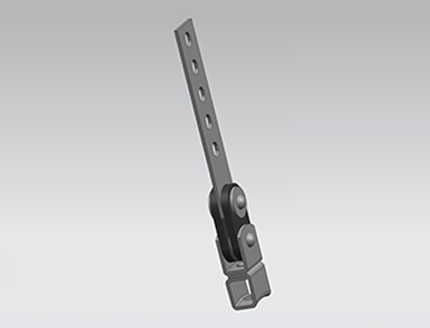

- Solid and 3-D modeling

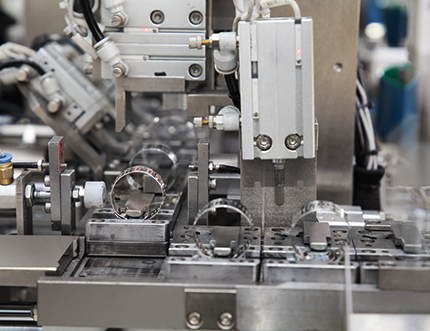

- VMM and CMM equipment

Aimed at the production with zero error policy, Winlong keeps the implement of production site management with 6S by the continuously training to ensure unbroken transfer of know-how from the general manager to every worker. From raw material to final product, each production is equipped with the “Lean Manufacturing” process in order to attain the customer satisfaction.

- Product defect rate: < 500ppm

- Production accident rate: 0

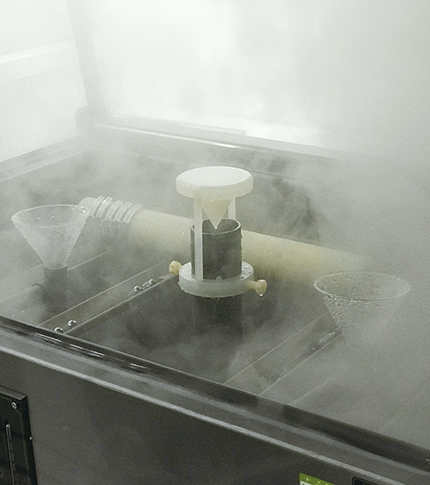

The professional testing equipments are the best support for R&D engineering and also the primary resource to certify the effectiveness of our product.

- Spectrum analyzer: raw material test

- Radiation detector: radiation test

- Hardness-testing device: hardness test

- Tensile Strength & Elongation Tester: load and tension test

- Steel wire torsion tester: torsion test

- Coupling hydrostatic tester - hydrostatic test

- Salt spray tester: salt spray test

- High-low temperature test chamber: thermal test, Ozone resistance life test

- Spring fatigue tester: spring life test